Illumination - Light Sources (Types of Lamps/Bulb)

Types of Electric lamp/bulb/luminaries

Incandescent

Lamp:-

An incandescent light bulb, lamp or incandescent light globe is an electric light with

a wire filament heated until it glows. The filament is enclosed in a bulb to

protect the filament from oxidation.

Current is supplied to the filament by terminals or wires

embedded in the glass.

Inventors are Joseph Swan, Thomas Edison

Incandescent Lamp fig:

Answer: Figure

Mercury Vapour discharge lamp :

What is Mercury Vapor Lamp ?

Definition: A lamp that consists of vaporized mercury to generate light by using an electric arc is known as a mercury vapor lamp. Basically, this lamp discharges gas when heated or cooled. The mercury which is present inside the tube is in liquid form (at room temperature) which is ionized before generating light. Its wavelength at low pressure ranges between 184 nm and 253 nm.

Principle: When mercury discharge

under low pressure gives mainly ultraviolet radiations. If pressure is

increased to one or two atmospheres, its proportion of radiations in visible

spectrum is increased and we get light having bluish tinge".

Construction and Working :

It consists of two tubes.

Inner tube contains neon or argon gas under low pressure . two main electrodes

in the form of oxide coated coils and starting or auxiliary electrode near the

cap end side of main electrode.

Inner tube is made of hard

glass and in an evacuated outer tube, which maintains high operating

temperature of the inner arc tube.

When supply is given ,

electric field is setup between the starting electrode and the adjacent main electrode.

This causes discharge first to take place between them through limiting carbon

resistance.

This discharge through

argon gas vaporize all mercury and for the lamp to reach full brilliance

requires 4 to 8 minutes depending upon the design.

Once arc tube is filled

with mercury vapour a low resistance path is created for current to flow

between the main electrodes. The are then shifts to main electrodes. Path of

starting electrode automatically becomes inactive.

Electrodes are kept in

electron emitting condition by the bombardment of heavy mercury ions.

Should the lamp go out

while in services , it will not restart till mercury vapour pressure has fallen

low enough to allow for restarting of discharge between main and auxiliary

electrodes

- Mercury discharge lamps

are made in five sizes viz. 80, 125, 250, 400 and 1000 W.

- In case of mercury vapour

lamps, magnitude of the striking, voltage is very much affected by ambient

temperature.

- Efficiency of these lamps

is of 30 to 40 lumen/watt and life is about 5000 hr.

Application : These are used for high ceiling manufacturing bays

street lighting , stage lighting ,

sport grounds , garages and petrol station lighting , railway marshalling yards

and park lighting, etc.

Compact Fluorescent Lamp (CFL)

Compact Fluorescent lamp Bulbs Construction and

working :

These are lamps of choice for those looking for

an energy efficient alternative to incandescent lamps

Atypical CFL

consists of a gas filled gas tube with two electrodes mounted in an end cap. It

contains a low pressure mix of argon gas, mercury vapour and liquid mercury and

is coated on the inside with three different phosphors.

They give off light

when exposed to ultraviolet radiation released by mercury atoms as they are

bombarded by electrons. The flow of electrons is produced by an arc between two

electrodes at the end of the tube.

Ballast provides

the high initial voltage required to create the starting arc and then limit

current to prevent the lamp from self destruction.

Ballast themselves

can be “standard" electromagnetic, "energy efficient electromagnetic

or electronic and may have power factor correction, radio interference,

suppression or other features unheard of in the world of incandescent light.

Colour :

With development of

more efficient "tri-phosphor" coatings came smaller 'CF with light in

red, blue and green giving white light when blended together.

By changing

relative balance of these phosphors, manufacturers can produce range of

apparent colour temperature from a cool 4100°C to a warm 2700°K.

Colour rendering

index of lamp reflect how accurately colour of an object can be determined

under given light source. CFL have CRI of 82 out of 100 while incandescent have

97 which is considered excellent for fluorescent sources.

Advantages

:

1.

More energy efficient than incandescent lamps: When

compared to incandescent lamps, fluorescent lamps can produce the same amount

of light or lumens using lesser energy input. Residential and commercial grade

fluorescent tubes and bulbs, including compact fluorescent lamps or CFL bulbs,

can produce 50 to 100 lumens per watt. Meanwhile, a typical incandescent bulb

produces 16 lumens per watt. This advantage translates to energy efficiency

than in turn, leads to reduced electricity consumption and cost.

2.

Longer operational lifespan: Another advantage of

fluorescent lamps over is their lifespan. A typical fluorescent bulb will last

10 to 20 times longer than an incandescent bulb. Specifically, fluorescent

lamps have an operational lifespan of 6000 to 15000 hours while incandescent

lamps only have 1000 hours. Due to their longer operational duration, one of

the notable benefits of using fluorescent lamps involve reduced time and cost

associated with replacement and maintenance.

3.

Better light diffusions and distribution:

Fluorescent lamps are bigger light sources than incandescent lamps. Furthermore,

most fluorescent bulbs or tubes readily diffuse light that results in better

distribution of illumination within a particular area. In contrast,

incandescent lamps are smaller light sources, and they produce undiffused light

as evident from glares and uneven illumination.

4.

Less heat emission: Incandescent lamps generate too

much excessive heat because they consume too much energy input. Hence, another

advantage of fluorescent lamps is less heat emission due to their efficient

energy consumption. Typical fluorescent bulbs such as CFLs convert of 22

percent energy input to visible light while incandescent lamps only use 5

percent of energy input to produce visible light and the remaining 95 percent

is converted into heat. This advantage translates further to other benefits

such as comfort and reduced cost from air conditioning and ventilation.

FLUORESCENT

LAMP(Tube):-

A fluorescent lamp consists of a glass tube

filled with a mixture of argon and mercury vapour. Metal electrodes at each end

are coated with an alkaline earth oxide that gives off electrons easily. When

current flows through the gas between the electrodes, the gas is ionized and

emits ultraviolet radiation. The inside of the tube is coated with phosphors,

substances that absorb ultraviolet radiation and fluoresce (reradiate the

energy as visible light).

Construction:

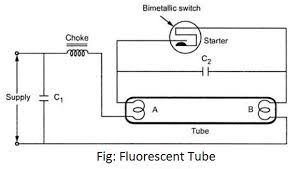

he above figure shows the constructional details of the Fluorescent Lamp. It consists of a long glass tube which is internally coated with a suitable amount of fluorescent powder. A small amount of mercury along with a little quantity of argon gas is also filled in the tube.

There are two electrodes A and B made up of coiled tungsten filament coated with an electron-emitting material. The control circuit of the tube contains glow type starter, choke L and two capacitors C1 and C2.

Working: When the supply is switched ON, an electric arc is established between the electrodes of the starter due to the flow of current through the small air gap between the electrodes. Due to this arc, heat is produced which is sufficient to bend the bimetallic strip which makes contact with the fixed electrode. This closes the circuit and therefore choke carries a large current. Once the electrodes close, the arc vanishes and bimetallic strips cool down again.

Now electrodes A and B become hot and due to cooling the choke circuit opens. The current through the choke coil is suddenly reduced to a small value. This change in current induces an e.m.f. which is very high of the order of 1000 V, in the choke coil. This e.m.f. induced is sufficient for ionizing the gas molecules between electrodes A and B which establishes the discharge between electrodes A and B through the gas.

The potential difference across the tube falls to about 100-110 V which is sufficient to maintain the discharge but not sufficient to restart the glow in the circuit.

So even if the starter is removed from the circuit, discharge continues as the current flows from electrodes A and B due to the ionization of the gas. If the supply voltage is low, there is difficulty in starting the tube as the low voltage is insufficient to establish a glow in the starter.

As the choke lowers the power factor, the capacitor C1 used in the circuit improves the power factor of the circuit.

The capacitor C2 suppresses the radio interference developed due to arcing. The function of the inductive choke is to supply a large voltage surge for establishing the discharge between electrodes A and B.

Advantages:

(i) The light available is much more than the normal incandescent lamp. A fluorescent lamp gives 2200 to 2400 lumens while a normal lamp gives 600 lumens.

(ii) The life of the fluorescent tube is much more than the incandescent lamp.

(iii)The fluorescent tube gives the effect of daylight while the incandescent lamp gives yellowish light.

(iv) Low power consumption.

(v) High efficiency.

(vi) Instantaneous switching without any warming period.

(vii) Using different fluorescent materials various coloured lights can be obtained.

Disadvantages: (i) Very high initial cost.

(ii) Produces radio interference.

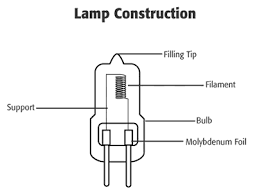

Halogen Lamp:-

A halogen lamp or tungsten halogen lamp is an incandescent lamp. The halogen lamp consists of a tungsten filament enclosed in an environment of an inert gas like argon and a small amount of a halogen like bromine or iodine. The combination of the tungsten filament and the halogen results in a chemical reaction (called regenerative cycle or halogen cycle).

This regenerative cycle increases the life span of the filament. Also, the halogen cycle prevents the darkening of the lamp envelope by redepositing the tungsten from the inside of the lamp back onto the filament.

Construction of Halogen Lamp

The halogen lamp consists of a filament of tungsten metal, which is enclosed in a fused silica quartz glass. This glass cover of the lamp is filled with an inert gas like argon and nitrogen. There are two terminal leads connected to the lamp filament for supply the power to the filament.

The use of halogen gas at low pressure in the lamp reduces the uneven evaporation of the filament and darkening of the glass cover. The halogen lamps can operate at a higher temperature than a standard gas filled incandescent lamp of the similar power rating without loss of its operating life.

Working Principle of Halogen Lamp

The working of the halogen lamp is based on the principle of thermal radiator, i.e. light is produced by heating a solid to a very high temperature. The brightness of the emitted light is proportional to the heating temperature. The halogen lamps have continuous spectral output. A major portion, up to 85%, of the light emitted by the halogen lamps lies in the infrared region, around 15% to 20% lies in the visible region and less than 1% lies in the ultraviolet region.

- There are two types of

mains voltage tungsten halogen lamp :

(a) Single ended.

(b) Double ended.

(a) Single ended halogen lamps :

- Single ended halogen

lamps have a compact filament inside a quartz envelope, which can be clear

or frosted (achieved by sandblasting the outer surface of the envelope).

They have caps to fit domestic lamp holders.

(b) Double ended halogen lamps :

- Double ended halogen

lamps are tubular lamps with , contact at each end . These contacts are

attached to a short pin emerging from the pinch seal , and recessed into a

ceramic insulator.

Advantages of halogen lamp :

- It is available in

miniature size, single ended or double ended lamps.

- No blackening of lamps.

- It has higher lumen

output 22-33 lumens/watt and high operating temperature.

- It has longer life about

2000 hrs and approximately double that of filament lamp

- It has better colour

radiation.

- Available in convenient

size

Disadvantage :

- Temperature under working

condition is very high.

- Bulb surface is sensitive

due to presence of liquid.

- Not as efficient as high

intensity discharge lamps.

Application :

- These are used in public halls, factories, photo-film OHP, Car lighting, large gardens, airport runways, sport halls, photo films, T.V., studios etc.

Metal Halide Lamp:

Construction of Metal Halide Lamp

The construction of a metal halide lamp is shown in the figure below −

A metal halide lamp consists of a metal base and a glass shield to protect the internal components of the lamp. Inside the glass shield, there is a series of lamps combined within a single arc tube with output characteristics of different mixtures of elements. The compact arc tube contains a mixture of argon, mercury and a variety of metal halides at high pressure.

Working of Metal Halide Lamp

When electric voltage is applied to the metal halide lamp, the argon gas in the lamp is ionized and facilitates striking of the arc across the two electrodes. The heat produced by the arc vaporizes the mercury and metal halides which produces light when the temperature and pressure increase.

The nature of the metal halides affects the nature of light produced by the lamp. Sometimes a phosphor coating is also provided on the inner side of the outer glass envelope to improve the spectrum and diffuse the light. To reach the full light output, metal halide lamps require around 3 to 5 minutes.

Metal halide lamps require electrical or electronic ballast to stabilize and regulate the arc current flow and to deliver the proper voltage to the arc.

Advantages of Metal Halide Lamps

- Metal halide lamps have high lamp efficiency around 60 to 115 lumens per watt.

- Metal halide lamps have long lifespan around 10000 to 20000 operating hours.

- Metal halide lamps do not require any starting gear.

Disadvantages of Metal Halide Lamps

- These lamps are not environmental friendly due to the presence of mercury.

- The cost of metal halide lamp is higher than incandescent lamp.

- Metal halide lamps produce high heat when in operation.

- Metal halide lamps require some starting time.

Applications of Metal Halide Lamp

Metal halide lamps are used in the following applications −

- High bay interior lighting

- Domestic and commercial lighting

- Sports stadium lighting

- Flood lighting, etc

Light Emitting Diode (LED):

A light-emitting diode (LED) is a semiconductor device that emits light when an electric current flows through it. When current passes through an LED, the electrons recombine with holes emitting light in the process. LEDs allow the current to flow in the forward direction and blocks the current in the reverse direction.

Working principle:

LEDs work on the principle of

Electroluminescence.

The energy is released in the form of photons

on recombination. In standard diodes, the energy is released in the form of

heat. But in light-emitting diodes, the energy is released in the form of

photons. We call this phenomenon electroluminescence. Electroluminescence is an

optical phenomenon, and electrical phenomenon where a material emits light in

response to an electric current passed through it. As the forward voltage

increases, the intensity of the light increases and reaches a maximum.

What determines the colour of an LED?

The colour of an LED is determined by the material

used in the semiconducting element. The two primary materials used in LEDs are

aluminium gallium indium phosphide alloys and indium gallium nitride alloys.

Aluminium alloys are used to obtain red, orange and yellow light, and indium

alloys are used to get green, blue and white light. Slight changes in the

composition of these alloys change the colour of the emitted light.

Advantages of LED

- consume very low amounts of power

- long lifespan

- More Energy efficiency

- More Durability

- Instant turn on

- Good Controllability

- No IR or UV Emissions

Neon Lamp:

A miniature gas discharge lamp in which the

electrical discharge takes place through a mixture of gases containing a large

proportion of neon gas is known as neon lamp.

The working principle

“Electrons are emitted from cathode by

subjecting the surface of the cathode to very high electric voltage so that the

electrons are forcibly ejected from the orbits of the atoms against the nuclear

centripetal forces.”

Construction of Neon Lamp

The construction of a typical neon lamp is

shown in the figure.

The neon lamp has two closely spaced electrodes, but not touching each other, in the form of thick parallel wire spiral or flat plate sealed within a soft glass envelope. The glass envelope is filled with the neon gas at a pressure of about 8 torr. Also, a series resistance of about 2000 ohms is mounted inside the cap.

Working of Neon Lamp

When a high electric power

supply is connected to the neon lamp, the cathode terminal starts emitting the

electrons. These electrons get accelerated by the electric field and collide

with the neon atoms. On collision, a part of the energy is transferred from the

electrons to the neon atoms and the neon atoms get excited. When the excited

neon atoms and ions come to their ground state, they give off light.

Some important points about the

working of neon lamp are listed below

In the neon lamps, the cathode

is heated for emission of electrons. For this purpose, these require a very

high voltage depending upon the distance between the electrodes.

In order to discharge the neon

gas, it requires a voltage equal to 1.5 to 2 times of the normal operating

voltage.

The strength of electric field

near the cathode is very high and the ions under the influence of stray field

will gain a lot of momentum which will cause disintegration of the cathode.

A very small lamp current will

give flickering of the gas discharge and a high lamp current will give a bright

stable discharge, but life will be shorter and blackening of the envelope will

occur. Therefore, the lamp current for a standard neon lamp is less than 1 mA

or fir a high brightness lamp is up to 2.5 mA.

When AC supply is used, each

electrode will turn positive and negative alternatively. Hence, a continuous

glow from the lamp is achieved.

Therefore, these types of neon

lamps are suitable for high operating voltage and low current applications.

Advantages

- The primary advantages of the neon lamps are as follows −

- The neon lamps are available in miniature configuration.

- Neon lamps have instant glow.

- Neon lamps are less expensive.

- These lamps consume less amount of electricity.

- They have long life around 5000 hours.

Disadvantages

- Neon lamps have low efficiency.

- Neon cannot be used for ordinary lighting purposes like domestic lighting, etc.

- Neon lamps have small range of color spectrum.

Applications

- Neon lamps are used as indicators such as red lights for hazardous warnings.

- Neon lamps are also used for advertising purposes.

- Neon lamps are used in display applications to show letters, numbers, etc.

- Neon lamps are used for decorative purposes.

LASER:-

Construction and Working of LASER

It contains a long crystal of made ruby with a flash tube (which is not shown for simplicity, instead directly pump light is shown) wrapped around it.

Here, a high voltage electric power supply makes the tube flash on and off. When the tube flashes, it pumps energy into the ruby crystal. The flashes it makes inject energy into the crystal in the form of photons. The atoms of the ruby crystal absorb this energy and thus the electrons of the atoms jump to a higher energy level.

Now, after few milliseconds, the electrons return to their ground level by giving off a photon of light, this is known as spontaneous emission. The photons that atoms give off zoom up and down inside the ruby crystal and travelling at a speed of light. One of these photons stimulate an already existing atom. When this happens, the excited atom gives off a photon and we get the original photon as well. This is known as stimulated emission.

Now, one photon of light has produced two photons so the light has been amplified. The escaping photons from the crystal form a very concentrated beam of powerful LASER light.

Types of LASER

- Gas LASER

- Liquid LASER

- Chemical LASER

- Semi-conductor LASER

- X-Ray LASER

Advantages of LASER

- LASER light travels to very long distances without any distortion

- LASER has high information carrying capability. Therefore, it can be used in data communication

- It is free from electromagnetic interference.

- LASER provides minimum signal leakage.

- LASER light is less harmful than X-rays.

Disadvantages of LASER

- LASER devices are very costly.

- While using LASER, safety precautions needed.

- LASER can damage the human organs.

- LASER requires other equipment like operating equipment and control gears, etc.

Applications of LASER

- For special lighting effects in media work.

- In computers, CD/DVD drives, etc.

- LASER light can be used for beautification.

- It can be used in medical equipment.

- LASER light is also used in metal processing industries.

- LASER is also used in defense applications.

Comments

Post a Comment

thanks for comment